Plans Drawing of Wood Wall Frame With Door and Window

Framing A Business firm

When viewing a framed house earlier the wall coverings are installed, the edifice often seems complicated and to some, a daunting project. House framing actually consists of several separate "projects" assembled into one to create the finished home. Taken in that context, house or building framing is not all that difficult. With today's advances in air tools, such as framing nailers, you don't fifty-fifty accept to exist an experienced hammer swinger to frame a house. Information technology is a adept idea, withal, for the inexperienced to begin with a small, simple construction, rather than a two story, complex design. A garage or garden shed is a good example. In about instances you will be amalgam from building plans, and that's definitely the easiest for the inexperienced. Brand sure you follow all specs and elevation drawings.

The most mutual framing material is wood, but metal framing is condign more than popular. Metal may be desired in some areas and may be a lawmaking regulation in other areas too. Regardless of the blazon of construction, make sure y'all cheque with local building authorities as to regulations pertaining to construction and framing, as well equally to obtain any needed permits.

Framing Methods

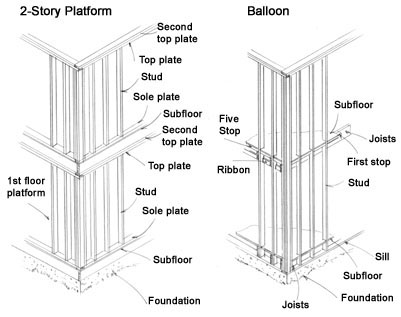

Two methods are used in standard wood house or "stick" framing—balloon or platform—and both have advantages and disadvantages. Balloon framing is sometimes used with 2-story buildings. In balloon framing the studs extend as ane, from the sill to the top plate of the second story. The second story floor joists are supported by a ribbon board set into the studs. This type of construction is the virtually difficult, but does provide unobstructed openings betwixt the floors allowing for easy installation of utilities without notching and cut openings. Fire stops must, still, exist installed at the second story floor level between the studs.

Platform framing tin can exist used for either single or two-story and is the easier and about common method of structure. Fire stops are automatically created with this type of construction. Constructing a unmarried-story is the easiest, a ii-story or separate level is harder. Platform framing is easier than balloon framing because yous can construct and erect the 2nd story walls on the 2nd story floors.

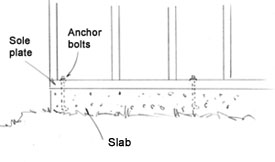

Either structure tin can be done on a concrete slab or on a foundation. The slab acts as a floor; a foundation requires a floor to first exist constructed. Then the walls are framed on the floor (or slab) and raised in identify.

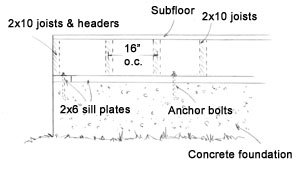

The most common construction is on a foundation. In this case the floor is outset framed, anchored to the foundation, and covered with a subfloor.

Build From the Floor Up

If constructing on a foundation, the first stride is to construct a floor on the foundation. Sill plates are anchored to the foundation, and so the floor joists are fastened to the sill plates and their ends boxed in with joist headers. The headers and outside joists should fit affluent with the outside edges of the foundation. Metal hangers make installing the joists easier than toe-nailing them in place.

In many instances of larger buildings, or those with joist spans over xvi anxiety, a girder is installed to provide back up for the floor at these locations. Today's girders are commonly made of engineered woods. The girder should exist supported by piers or foundation and footings. With the flooring framed in, decking, or a subfloor, is added. Decking is typically oriented-strand lath (OSB), or three/four-inch plywood sheathing. In the by solid wood one-by boards were applied on the diagonal.

Wall Construction

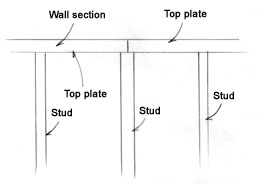

After the deck or floor has been synthetic, you're prepare to construct and cock the walls. The walls consist of sole plates nailed to the subflooring, or anchored with ballast bolts to the concrete slab. Studs are nailed to the sole plates and top plates are nailed to the studs.

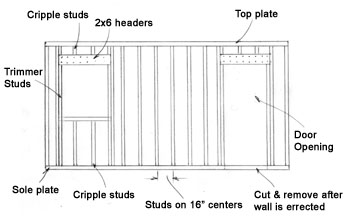

Actually, the walls are assembled in one piece, or in the case of long walls, in sections joined together to create the length needed. If building on a slab, the first pace is to lay the sole plate on the slab and mark the locations of the anchor bolts. Bore these holes. Regardless of whether you are building on a slab or foundation, the next step is to lay the sole plate and acme plate next, and determine whatever door and window locations, equally per the plans or your building blueprint. Y'all must know the rough-opening sizes of whatever doors and windows. Using a carpenter'due south square, mark these rough opening locations on both. The natural language of the foursquare is 1-ane/2-inches wide, the verbal width of kiln-dried two-past framing materials. Then marking the stud locations, again on both sole and elevation plate at the same time. This measurement may be on 16- or 24-inch centers, depending on building design or local codes.

Once all measurements have been marked on both sole and top plate, lay them on edge on the subfloor or physical slab, the proper altitude apart of the stud lengths. If y'all use precut studs you can save money and time. Fasten the studs between the plates, positioning their ends in the previously marked locations.

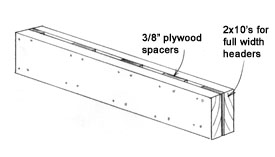

Once the studs are in place, frame in the door and window openings, and then add the headers. Headers may be constructed full width past using 2-by-ten's, or they may be created by using two-by-6'south filling in above them with cripple studs. Traditional headers are created past nailing 3/8-inch plywood spacers between the header boards to create the aforementioned thickness in the header as the three-i/two-inch width of the studs. The headers are supported by trimmer studs to create doubled studs in the openings. Cripple studs are fastened between the trimmers beneath the door and window openings, and spaced to match the other studs on the same xvi- or 24-inch centers.

A framing air nailer can save time if you accept ability to the site. If there is no power y'all can utilize a cordless model such equally the Paslode. Several years ago my daughter helped frame a building and she had never "swung a hammer." Using an air framing nailer, she had no issues, and we completed the edifice in a short fourth dimension.

Squaring the Frame

In some instances walls are constructed without additional bracing, using plywood or OSB capsule at the corners to brace and square the wall department. And in some cases the sheathing is applied to the wall frame before erecting the wall. In either case the wall section is first squared by measuring diagonally from corner to corner, then from opposite corner to corner and shifting the wall section to create an equal measurement and a squared wall. A large wooden 90-caste triangle can as well be used. A temporary brace is then installed to concord the wall square.

In many instances hurricane bracing is added to the walls. This consists of purchased metallic strips or 1-by-4'due south gear up diagonally beyond the wall and cut into the exterior edges of the 2-by-4's. With sole plate and top plate nailed into the studs, again use a record measure to mensurate diagonally from corner to corner and square up the wall. Temporarily tack the hurricane bracing in place and mark the cut locations. Employ a saw to cut the notches, and then remove material between the saw marks with a chisel. Anchor the bracing in place with 2 8d nails at each stud, and and so cutting the ends of the bracing off flush with the plate edges. (Make certain you bank check with local codes on bracing regulations in your area.)

Raising the Walls

Erecting a wall is fairly like shooting fish in a barrel, but fifty-fifty pocket-sized walls are all-time erected past at least 2 people. Erecting on a subfloor is easier than on a slab. Only slide the wall close to the edge at its location and tilt information technology upward. I like to use temporary 2-by-four stop blocks fastened to the outside edges of the joists and headers to keep the wall from sliding off as you lift it upwardly. If installing the wall on a physical slab, slide it up to the anchor bolts, then you will have to lift the wall upward and position information technology down on the anchor bolts. Again, this is at least a two-person chore, fifty-fifty for a brusque wall.

With the wall up in position, drive 2-by-4 stakes in the footing and provide temporary supports anchored to the wall studs and stakes. Duplex nails used for constructing foundations are adept for this step, as they tin more easily exist pulled later. Make sure the wall is plumb and correctly in position before anchoring the bracing. If placed on a slab, fasten the sole plate in place with washers and nuts over the sole plate and on the anchor bolts. If on a foundation/floor, nail the sole plate down on the subfloor and into the floor joists and headers. If the wall is to be built in sections, build the side by side section, erect it, brace in place and fasten to the previously erected wall. Annotation the wall joints are always on a stud.

Construct, erect and brace the contrary wall in place in the same fashion. And then construct the wall that fits between the two standing walls. This wall is measured to fit between the previously erected walls, measuring at the bottom. Construct and cock the opposite-stop wall in the aforementioned manner. On these walls, start with studs on each end, and then measure for the "on-centre" studs, adding the 2-past-4 or 2-past-6 measurement of the studs on the previously erected walls. Every bit with the other walls, openings are framed in the aforementioned manner and bracing applied. In whatsoever case these walls are erected between the two bordering walls, plumbed and then anchored to the outside studs on the two bordering walls. Caryatid the eye section to keep it from bowing out or in.

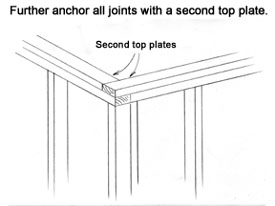

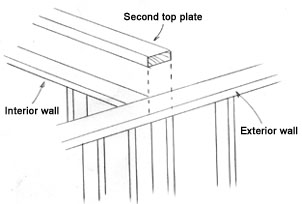

If the building is not rectangular or square, but has extensions, construct these walls, joining at the corners, again basically creating two "sides" and then erecting the ends to join the opposite walls together. The tops of the walls at corners and wall department joints are joined by nailing a second top plate downward over the top plate, crossing over all joints to tie them securely together. This second top plate creates the last wall peak of a standard viii-foot wall.

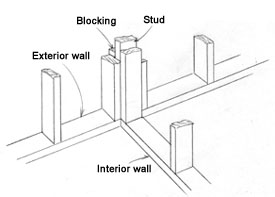

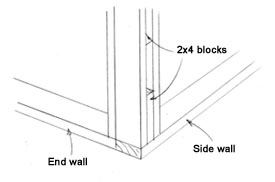

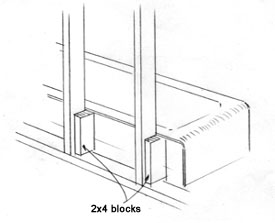

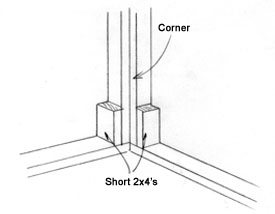

Using a handsaw, cutting and remove the section of sole plate at the bottom of each door opening. Corner blocking is added at corners to provide a square corner for installation of interior wall coverings. This may exist done in several ways, equally shown in the diagrams. Interior walls are framed, erected and anchored in place in the same mode, over again using a second top plate to tie them together and to the outside walls. Corner blocking is needed at each interior wall corner to provide for fastening interior wall coverings. Afterward erection of the walls, you're fix to install ceiling joists on superlative of the walls. If constructing a second story platform-manner, you just echo the unabridged process. Again amalgam a floor on top of the walls, and then constructing and erecting the second-story walls.

Framing Details

Framing details added during wall structure volition make it easier to finish off a edifice. For case y'all can add together wall bankroll to any tub and faucet inlet areas, also as wall-hung appliance locations. This will make it easier to install all of these and is easier to do during wall structure than subsequently the walls have been erected. You can likewise add together blocking to help back up tubs. Some builders fasten in additional brusk blocking at each corner about the floor to provide better back up for nailing baseboards in place. This allows you to nail the baseboards further back from their ends and prevent splitting out the ends. Bridging can be installed in the floor between joints during structure to create a meliorate quality and "less squeaky" floor.

Framing a building doesn't have to be daunting if you take it one step at a time, follow plans and regulations and start simple.

Source: https://extremehowto.com/understanding-house-framing/

0 Response to "Plans Drawing of Wood Wall Frame With Door and Window"

Enregistrer un commentaire